Why Is Acrylic Needle Punched Filter Felt a Popular Choice for Flue Gas Filtration with High Air Volume?

In the realm of environmental protection and industrial filtration, choosing the right filter material is crucial. With increasing emphasis on air quality and emissions control, businesses are seeking advanced filtration solutions that can efficiently handle high volumes of flue gas while maintaining optimal performance. Among the various options available, acrylic needle punched filter felt stands out as a popular choice, particularly for applications requiring high air volume filtration.

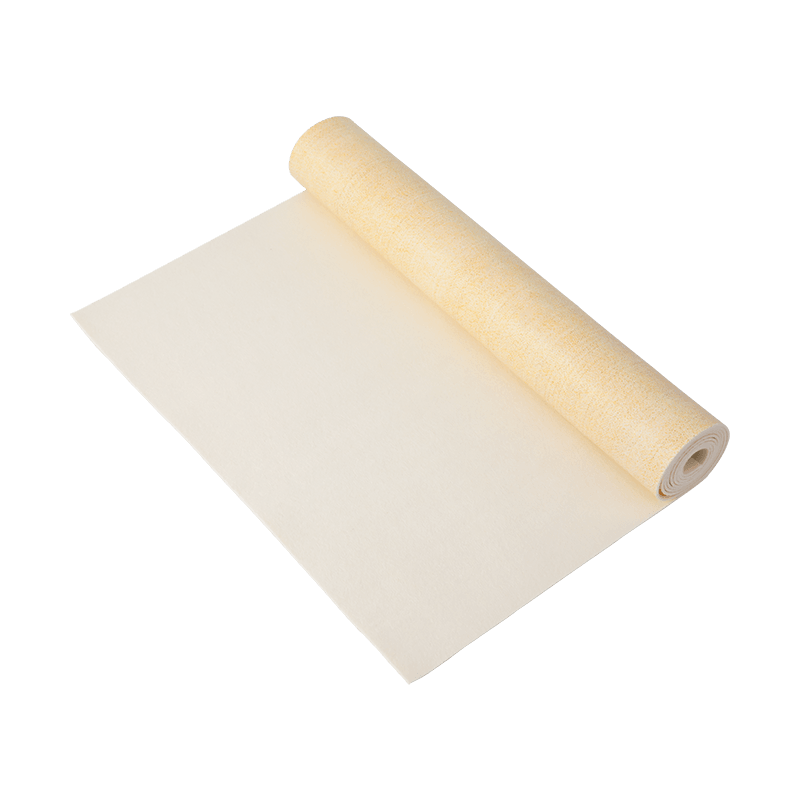

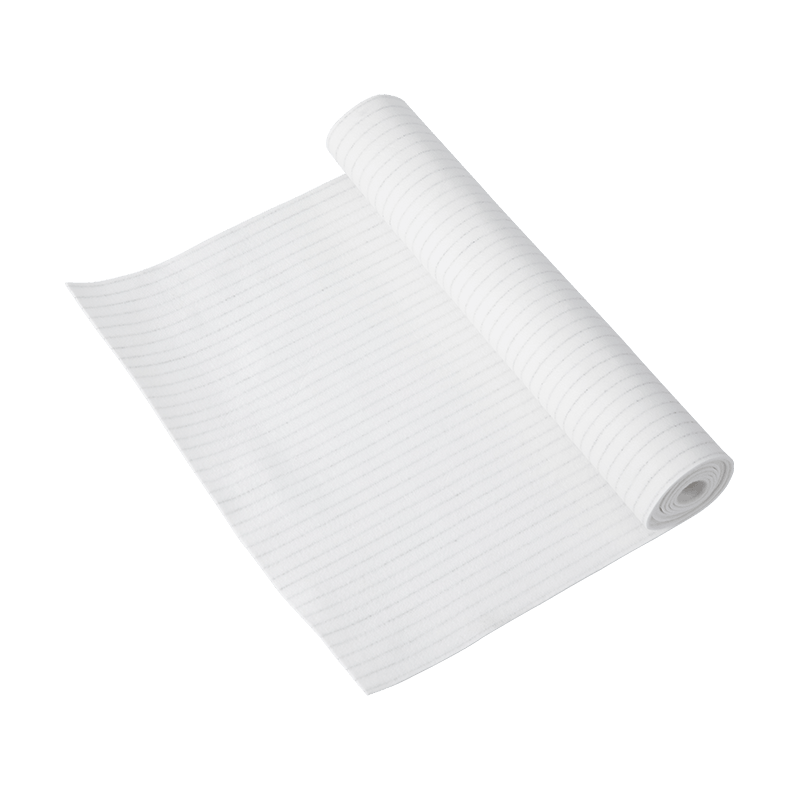

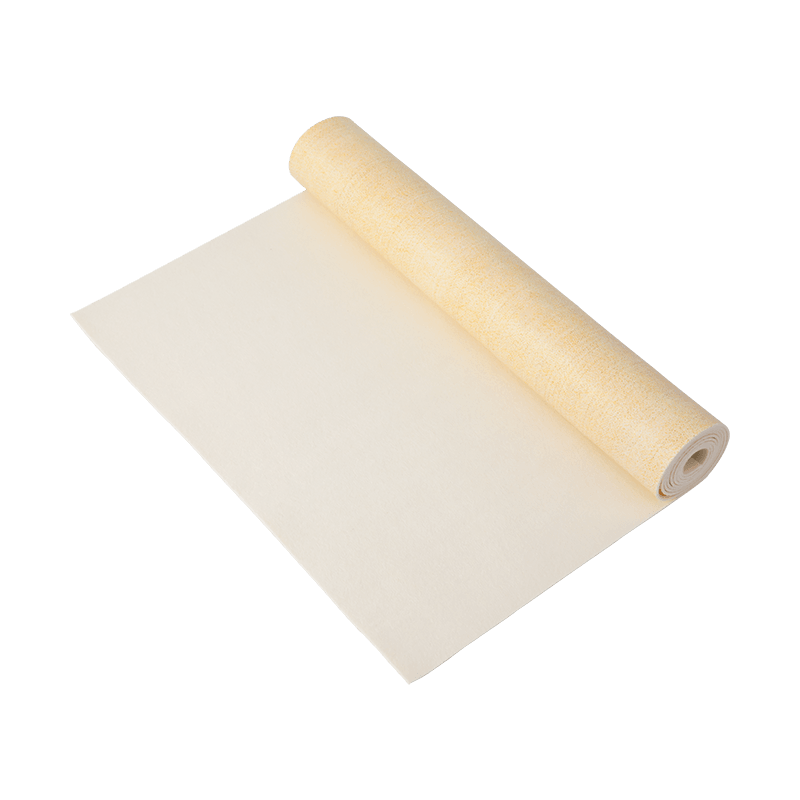

Acrylic needle punched filter felt is renowned for its exceptional durability and resilience. Made from high-strength, low-elongation industrial filaments, this filter material boasts a robust construction that can withstand the rigorous demands of high-volume flue gas filtration. The needle punching process enhances the fiber entanglement, creating a dense and stable structure that effectively traps dust particles and extends the filter's lifespan.

Moreover, acrylic needle punched filter felt excels in maintaining air permeability. Its finely tuned filtration pore diameter allows for the efficient passage of air while effectively blocking and collecting dust particles. This balance ensures that the filtration system operates smoothly, minimizing pressure drop and maintaining optimal flow rates, even under high-volume conditions.

At Jiangsu Dongwang, we take pride in our commitment to innovation and quality. Our acrylic needle punched filter felt undergoes rigorous testing and quality control to ensure it meets the highest standards in the industry. Our team of experts continuously strives to improve the material's performance, incorporating advanced technologies and techniques to enhance its durability, filtration efficiency, and hydrolysis stability.

In addition to its technical advantages, acrylic needle punched filter felt offers significant economic benefits. Its long lifespan and high efficiency reduce the frequency of filter replacements and maintenance, lowering operational costs and minimizing downtime. This, in turn, allows businesses to focus on their core operations, driving productivity and profitability.

Our company's expertise extends beyond filter materials. We specialize in the production of a wide range of industrial filtration products, including dust filter bags, liquid filter cloth, and filter bags, as well as framework series products, dust collector supporting series, electromagnetic pulse valve supporting series, and filter cartridge supporting series products. This comprehensive portfolio allows us to provide tailored solutions that meet the unique needs of our clients.

English

English Español

Español عربى

عربى

-1.jpg)

.jpg)